High demand for diamonds has led to the development of methods for producing synthetic diamonds. Even though the majority of natural diamonds are industrial grade, only about 10 percent of the diamonds used for industrial purposes are natural diamonds. The other 90 percent are synthetic diamonds.

High demand for diamonds has led to the development of methods for producing synthetic diamonds. Even though the majority of natural diamonds are industrial grade, only about 10 percent of the diamonds used for industrial purposes are natural diamonds. The other 90 percent are synthetic diamonds.

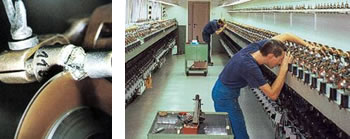

Industrial uses of synthetic diamonds range from the diamond grill bits used in mining and oil exploration to the diamond laser knifes used in intricate surgery.

Since it takes a diamond to cut a diamond, there are many industrial uses of synthetic diamonds in the diamond industry to cut natural gem quality diamonds. The diamond saws illustrated below are a key tool used in the diamond cutting process.

The two most common processes of synthesizing diamond are the high-temperature high-pressure (HTHP) and chemical vapor deposition (CVD) methods. The HTHP method converts carbon to diamond at high temperature and pressure using a molten metal catalyst. The HTHP method is sometimes also used to change or enhance the colors of some rare natural diamonds, thus making them more valuable on the market. The CVD method produces diamond coatings by heating a hydrocarbon gas over a metal surface. These diamond coatings greatly extend the lifetimes of precision dies, drills, and saw blades.

Synthetic Diamonds: Future Uses

As methods for growing diamond, both at high pressure and by chemical vapor deposition (CVD) improve, and as science finds ways to take advantage of diamond’s properties, the potential applications of diamond’s superlative properties appear boundless. From super electronics, to strong optical windows, to unscratchable surfaces, synthetic diamond is an obvious choice.

Managing heat, particularly in electronics, with large layers of synthetic CVD diamond is a rapidly expanding field. One of the most imaginative of these is the three-dimensional multi-chip module, which holds out the promise of an extremely powerful supercomputer. To gain speed, electronics need to be as compact as possible, concentrating waste heat as well. By stacking sandwiches of electronics and synthetic CVD diamond, a supercomputer could be made small and cool enough to function.

The use of diamond as a semiconductor requires the highest purity, best crystallinity and the introduction of electrically active atoms to create the electrical pathways of the device. But almost all natural diamonds are unsuitable for electronics due to defects, impurities and poor structure. Even gem-quality natural and created diamonds, while valuable, may not be suitable as semiconductors because of trace impurities. Only the purest of these stones are usable in high-powered electronic applications from cell phones and personal computers to secure communication lines.

Diamond windows for infrared devices are under development and should find their way into the tough environment of laser-guided smart bombs and more constructive uses in industry as well. The use of synthetic diamonds as radiation detectors, light emitters in electronic displays, and coatings to make surfaces indomitable or unwettable are being researched now. Beyond their imprint as a tool, synthetic diamonds will be showing up in more and more products in the future, probably in your home electronics, appliances, and automobiles.

Synthetic Diamonds: Production

Diamond was discovered to be carbon in 1796, and it took more than 150 years from that time until a method of diamond synthesis was invented. The secret was pursued by many scientists but not unlocked until the 1950s, when diamond was synthesized almost simultaneously by Swedish and American researchers. Pressures of over 55,000 atmospheres and 1400C, plus molten iron to facilitate the change from graphite to diamond, were necessary. Now some 80 tons of synthetic diamonds are produced annually by General Electric, De Beers, and many others for industrial firms.

In nature, diamonds crystallize under high pressures deep within Earth over long periods of time. In the lab, two distinct processes can create diamonds in much shorter periods of time. The high-pressure high-temperature (HPHT) process essentially mimics nature’s process for creating diamonds, while chemical vapor deposition (CVD) does the exact opposite. Instead of pressurizing carbon into creating diamonds, CVD frees carbon atoms to allow them to join together to create a diamond.

Both processes quickly grow gem-quality diamonds, but ultimately, the CVD process is going to be most useful in electronic technologies because its impurities and size can be easily controlled. Synthetic diamonds have been produced in a variety of colors including yellow, blue, green, pink, red, purple, and colorless. Although they are nearly physically, optically and chemically identical to their natural, mined counterparts, these synthetic diamonds can be identified by a trained gemologist using standard gem-testing equipment and techniques.

CVD begins with a tiny diamond seed that is placed in a vacuum. Then hydrogen gas and methane are flowed into the vacuum. Plasma splits the hydrogen gas into atomic hydrogen, which then reacts with the methane to produce a methyl radical and hydrogen atoms. The methyl radical attaches to the diamond seed to grow the diamond. CVD diamond growth is a linear process, which means that the only limiting factors in size are how big the seed is at the start with and how long it is left in the machine.

CVD begins with a tiny diamond seed that is placed in a vacuum. Then hydrogen gas and methane are flowed into the vacuum. Plasma splits the hydrogen gas into atomic hydrogen, which then reacts with the methane to produce a methyl radical and hydrogen atoms. The methyl radical attaches to the diamond seed to grow the diamond. CVD diamond growth is a linear process, which means that the only limiting factors in size are how big the seed is at the start with and how long it is left in the machine.

HPHT also begins with a tiny diamond seed. In washing-machine-sized diamond growth chambers, each seed is bathed in a solution of graphite and a metal-based catalyst at very high temperatures and pressures. Under highly controlled conditions, the small diamond seed begins to grow, molecule by molecule, layer by layer, emulating nature’s process. While General Electric pioneered this diamond-creation process and has since been selling HPHT-created diamonds for industrial uses, the diamonds were not sold as gemstones until Gemesis simplified the process and was able to create much higher quality diamonds.

Synthetic Diamonds: Gemesis

Both Apollo Diamond and Gemesis are now selling synthetic gem-quality diamonds commercially. These synthetic diamonds sell for significantly less money than natural diamonds. Since 2003, Gemesis has been selling synthetic “fancy-colored” diamonds at prices that are one-fourth to one-fifth of the price of natural fancy-colored stones of comparable color, clarity, cut and carat weight. High-quality fancy-colored diamonds make up a small and highly lucrative part of the diamond industry. Exceedingly rare and thus much more expensive than their colorless counterparts, these diamonds range in color from red and pink, to blue and green and even bright yellow and orange, depending on the impurities.

Both Apollo Diamond and Gemesis are now selling synthetic gem-quality diamonds commercially. These synthetic diamonds sell for significantly less money than natural diamonds. Since 2003, Gemesis has been selling synthetic “fancy-colored” diamonds at prices that are one-fourth to one-fifth of the price of natural fancy-colored stones of comparable color, clarity, cut and carat weight. High-quality fancy-colored diamonds make up a small and highly lucrative part of the diamond industry. Exceedingly rare and thus much more expensive than their colorless counterparts, these diamonds range in color from red and pink, to blue and green and even bright yellow and orange, depending on the impurities.

Learn more about Gemesis at www.gemesis.com

Synthetic Diamonds: Apollo

Apollo Diamond has taken a different route, selling colorless stones, though the company will soon sell blue, pink and black diamonds as well. The diamonds produced can be very high quality: Even machines built by the diamond industry to distinguish synthetic from natural stones can have trouble telling them apart, which has some major diamond sellers in the industry scrambling.

Apollo Diamond has taken a different route, selling colorless stones, though the company will soon sell blue, pink and black diamonds as well. The diamonds produced can be very high quality: Even machines built by the diamond industry to distinguish synthetic from natural stones can have trouble telling them apart, which has some major diamond sellers in the industry scrambling.

Many assets of Apollo Diamond were acquired by Scio Diamond Technology Corporation in 2011, which said that it plans to produce synthetic diamond at its South Carolina facility using Apollo Diamond technology.

Synthetic Diamonds: LifeGem

A truly unique approach to making man-made diamonds is the LifeGem®, a diamond made from the carbon remains of family members or pets. Marketed as a “diamond tribute for you and your family,” the company captures carbon from a loved one’s cremation, the hair from a loved one’s burial, or the live hair from someone with whom you have a special relationship. The carbon can even be captured from a pet.

A truly unique approach to making man-made diamonds is the LifeGem®, a diamond made from the carbon remains of family members or pets. Marketed as a “diamond tribute for you and your family,” the company captures carbon from a loved one’s cremation, the hair from a loved one’s burial, or the live hair from someone with whom you have a special relationship. The carbon can even be captured from a pet.

The carbon is heated under controlled conditions to produce graphite, which is then placed in a unique diamond producing hydraulic press. Under high temperature and pressure, the graphite transforms into a rough diamond crystal in about twenty-four weeks. The longer the time in the press, the larger the size of the diamond crystal formed. The rough diamond crystal is then cut into the shaped desired by the customer with a laser inscription on the girdle.

Most man-made or synthetic diamonds are marketed as being less expensive than natural, mined diamonds but that is not the case with LifeGem® which uses the emotional power of losing a loved one to obtain prices much higher than natural diamonds. Prices start at about $3,000 for a fourth of a carat, over $6,000 for half-carat stones, and $15,000-$20,000 for a one-carat stone.

The LifeGem® marketing strategy is evident in slogans like:

- An everlasting connection to the one you have lost

- You have your loved one with you and in your life for all times

- A treasured heirloom in your family for generations to come

- Tells a unique story and represents a new beginning

Founded in 1999, LifeGem’s headquarters are in Elk Grove Village, Illinois and they have offices in Europe, United Kingdom, Japan, Taiwan, Australia, and Canada. LifeGem partners with funeral homes and cremation service businesses to in those countries to collect the carbon remains.

Synthetic Diamonds: D.NEA

D.NEA (formerly Adia Diamonds), headquartered in Battle Creek, Michigan, uses the high pressure, high temperature (HPHT) process to produce gem-quality man-made diamonds. The D.NEA brand of synthetic diamonds are created in a laboratory in Europe and then cut in Antwerp, Belgium. The D.NEA diamonds are then marketed through its retail partner, Pearlman’s Jewelers, and online at their d.neadiamonds.com website.

D.NEA (formerly Adia Diamonds), headquartered in Battle Creek, Michigan, uses the high pressure, high temperature (HPHT) process to produce gem-quality man-made diamonds. The D.NEA brand of synthetic diamonds are created in a laboratory in Europe and then cut in Antwerp, Belgium. The D.NEA diamonds are then marketed through its retail partner, Pearlman’s Jewelers, and online at their d.neadiamonds.com website.

The laboratory-created diamonds are produced in white, yellow and blue colors. Prices for yellow diamonds appear to be about half the price of similar natural yellow diamonds.

Marketing for D.NEA stresses that they are ecologically friendly and conflict-free. An interesting advertising gimmick is to compare the annual production of D.NEA to natural diamonds to imply that D.NEA are the truly rare diamonds. The implication is that there is an abundance of natural diamonds and that it is the diamond industry that creates the illusion of rarity to increase prices. What this approach fails to mention is that the global production of natural diamonds is expected to drop 10% over the next 7-10 years while global demand is increasing 5-7% per year. Just because large numbers of natural diamonds are mined does not mean there is a surplus and prices should be lower.

Adia Diamonds was re-branded to D.NEA in early 2008 to put a stronger emphasis on jewelry.

Synthetic Diamonds: Chatham

For over 60 years, Chatham Created Gems has been a leader in man-made rubies, sapphires, alexandrites, and opals. Now Chatham uses the high pressure, high temperature process to create cultured diamonds.

Chatham created diamonds are available in shades of yellow, pink and blue. Yellow diamond prices are priced about the same as natural white diamonds with pink and blue colors about 50% greater.

The Chatham marketing strategy for diamonds is to emphasize their long history of producing synthetic gemstones and to utilize their network of jewelers in the United States who sell The Chatham Collection of jewelry.

Synthetic Diamonds: Tairus

TAIRUS is a Joint Venture between the Russian Academy of Sciences (Siberian Branch) and Tairus (Thailand) Co LTD of Bangkok. Tairus produces a variety of synthetic gemstones using the Hydrothermal process, including emerald, ruby, sapphire, and Beryl. Synthetic diamond production is relatively recent and the company continues to improve the quality and color of the diamonds it produces using the high pressure, high temperature (HPHT) process with alkaline carbonate-fluid melts.

TAIRUS is a Joint Venture between the Russian Academy of Sciences (Siberian Branch) and Tairus (Thailand) Co LTD of Bangkok. Tairus produces a variety of synthetic gemstones using the Hydrothermal process, including emerald, ruby, sapphire, and Beryl. Synthetic diamond production is relatively recent and the company continues to improve the quality and color of the diamonds it produces using the high pressure, high temperature (HPHT) process with alkaline carbonate-fluid melts.

The Tairus synthetic diamonds are primarily Fancy Yellow colors including Vivid Yellow, Orange, and Cognac. White and blue colored diamonds are much more difficult to produce and are not yet perfected for production.

Supplies of Tairus diamonds are very limited and are sourced from their Bangkok, Thailand location via online inquiries.

Synthetic Diamonds: New Age Diamonds

The New Age Diamonds Company is a Russian manufacturer of synthetic diamonds. Using the high pressure, high temperature (HPHT) process, the laboratory produces man-made gem-quality diamonds.

The New Age Diamonds Company is a Russian manufacturer of synthetic diamonds. Using the high pressure, high temperature (HPHT) process, the laboratory produces man-made gem-quality diamonds.

New Age Diamonds implemented a unique marketing approach in Japan where “Heart-in Baby Diamonds” are cultivated from newborn baby hair. This is just one of many commemorative New Age Diamonds that are custom made from the hair of people or fur of pets, either living or dead.

Cultivated diamonds from New Age Diamonds are available in a variety of colors with yellows being the least expensive and Deep Red the most expensive. The prices for these synthetic diamonds start in the $4000-$6000 range for one-carat stones.

Synthetic Diamonds: D.NEA

![]() D.NEA is based in Greenville, South Carolina USA and produces gem quality synthetic diamonds in yellow, blue, and white colors. It claims to be the first company to produce these gem quality stones in these colors.

D.NEA is based in Greenville, South Carolina USA and produces gem quality synthetic diamonds in yellow, blue, and white colors. It claims to be the first company to produce these gem quality stones in these colors.

The company was re-branded from Adia Diamonds in early 2008. The diamonds are created using the HPHT (High Pressure, High Temperature) technology in a laboratory in Europe, cut in Antwerp, Belgium and then marketed through the privately held D.NEA company.

Synthetic Diamonds: Scio Diamond Technology

Scio Diamond Technology Corporation is a synthetic diamond manufacturer that produces gem quality and industrial diamonds in Greenville, South Carolina. The company uses the CVD (Chemical Vapor Deposition) pioneered by Apollo Diamond. The technology and assets of Apollo Diamond were acquired by Scio Diamond Technology Corporation in 2011.

Scio Diamond Technology Corporation is a synthetic diamond manufacturer that produces gem quality and industrial diamonds in Greenville, South Carolina. The company uses the CVD (Chemical Vapor Deposition) pioneered by Apollo Diamond. The technology and assets of Apollo Diamond were acquired by Scio Diamond Technology Corporation in 2011.

Synthetic Diamonds: Detection Techniques

Diamond labs in Belgium and elsewhere that traditionally analyzed and certified diamonds larger than one carat for color and clarity are now being asked to distinguish between natural and synthetic or artificially colored diamonds. With current technologies, the labs can identify synthetics and treatments. But it’s not a perfect science, especially as the diamond-growth and treatment technologies get better.

Some of the laboratories employ two types of machines to detect synthetic diamonds. The first shines light through the diamond and analyzes the spectral characteristics of the absorbed or emitted light. If it finds indications of a synthetic diamond, the labs use a secondary machine that utilizes ultraviolet light to reveal the crystal’s inner structure. These machines examine defects in the diamonds, even microscopic or atomic.

Diamonds are just like trees with growth rings surrounding an inner core. Diamonds that are lab-created or treated (to change the color of a natural stone) exhibit a different structure. Thus, while labs that use these machines can distinguish created from natural diamonds, the worry in the diamond industry is that people without these machines will not be able to detect synthetically created diamonds.

The average consumer or even jeweler will not be able tell a difference. While the diamond industry says it has “no problem with synthetic diamonds,” they want to ensure that the created diamonds are clearly labeled so that consumers know what they are getting.

Both Gemesis and Apollo are working to ensure the authenticity of their synthetic diamonds. For example, all Gemesis cultured diamonds greater than 0.25 carat are laser-inscribed with the Gemesis name and a serial number. In addition, all Gemesis synthetic diamonds greater than 1 carat are accompanied by a certificate of authenticity from the European Gemological Laboratory USA. But the question remains, whether everyone who eventually creates synthetic diamonds will be as conscientious.

Both Gemesis and Apollo are working to ensure the authenticity of their synthetic diamonds. For example, all Gemesis cultured diamonds greater than 0.25 carat are laser-inscribed with the Gemesis name and a serial number. In addition, all Gemesis synthetic diamonds greater than 1 carat are accompanied by a certificate of authenticity from the European Gemological Laboratory USA. But the question remains, whether everyone who eventually creates synthetic diamonds will be as conscientious.

Synthetic Diamonds: The Future

While synthetic diamonds are expected to have a market niche of their own in the jewelry industry, the big payoff is expected to be in industrial technologies.